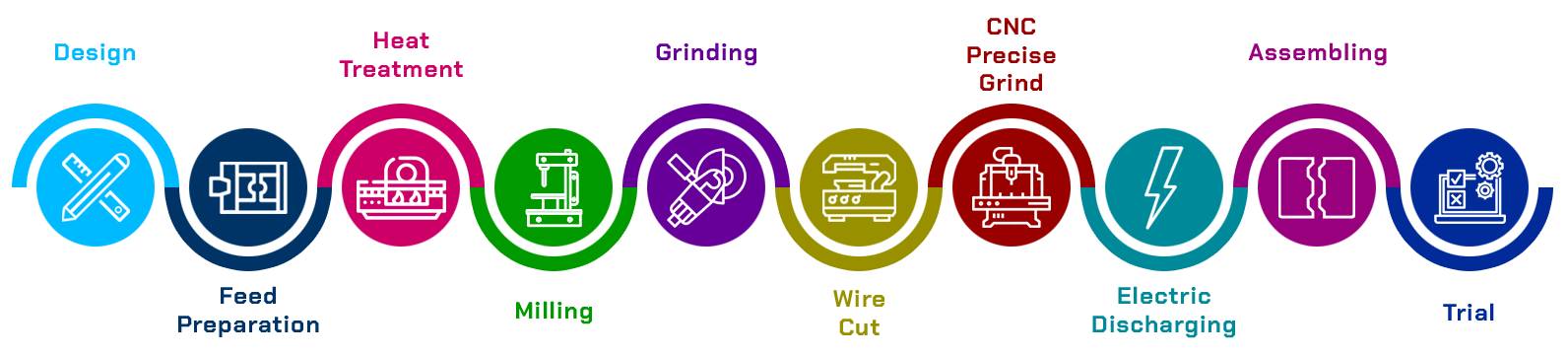

Manufacturing design and tooling design services from our committed engineering team allow us to offer any consulting services, cost control analysis and manufacturability analysis. Our design engineering capabilities include AutoCAD, 3D design with Diemaker and latest applications/software as NX Solid works and a range of services such as design assistance, material selection consultation, and prototype development.

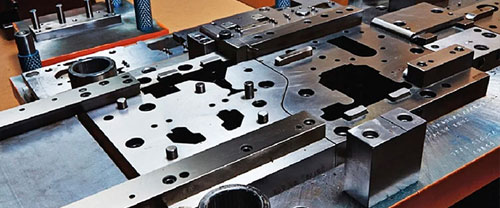

At SRE we are able to customize progressive die designs and mould as per customer specifications along with the ability to provide in-house production as well. We have successfully developed complex press tool to our customers.

Mould manufacturing plays a crucial role in the plastic moulding industry. It involves the creation of moulds, also known as tooling or dies, which are used to shape molten plastic materials into various packaging products. These moulds are used in processes like injection moulding, blow moulding, and thermoforming to produce a wide range of plastic items such as toys, rubber parts, automobiles parts, bottles, containers, caps, lids, trays, and more.

We specialize in the design, development and manufacturing of high speed stamping progressive tools, prototype tools, plastic injection moulds.

Our facility is equipped with the latest machinery and technology, enabling us to cater to a wide range of industries and applications. Here are some key reasons to choose SRE Tool and Dies for your business:

With years of experience in the industry, our team of skilled engineers and technicians possesses the expertise to handle projects of varying complexities.

We understand that the quality of the mould plays a vital role in the final product's outcome. SRE Tool and Dies uses advanced tools and equipment to design and manufacture high-precision tools and moulds that guarantee accuracy and repeatability in every production cycle.

Choosing the right material for your project, is critical to achieve the desired properties, productivity and performance. SRE Tool and Dies offers a wide selection of materials, including engineering-grade plastics and elastomers, to meet the specific requirements of your application.

Whether you need a small batch of prototypes or a large-scale production run, we have the flexibility to accommodate your project's unique demands. Our agile manufacturing processes ensure timely delivery without compromising on quality.

Quality is at the core of our operations. SRE Tool and Dies adheres to strict quality control standards throughout the production process. We conduct comprehensive inspections and testing to ensure that the final products meet or exceed your expectations.

10+

Years of Experience

15

Happy Clients

12

Number of Engineers

45

Number of Employee