Design & Engineering

Manufacturing design and tooling design services from our committed engineering team allow us to offer any consulting services, cost control analysis and manufacturability analysis. Our design engineering capabilities include AutoCAD, 3D design with Diemaker and latest applications/software as NX Solid works and a range of services such as design assistance, material selection consultation, and prototype development.

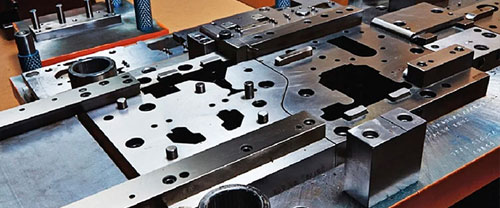

Tooling

At SRE we are able to customize progressive die designs and mould as per customer specifications along with the ability to provide in-house production as well. We have successfully developed complex press tool to our customers.

Mould Manufacturing

Mould manufacturing plays a crucial role in the plastic moulding industry. It involves the creation of moulds, also known as tooling or dies, which are used to shape molten plastic materials into various packaging products. These moulds are used in processes like injection moulding, blow moulding, and thermoforming to produce a wide range of plastic items such as toys, rubber parts, automobiles parts, bottles, containers, caps, lids, trays, and more.

Project Management

Project management in the plastic moulding industry involves the systematic planning, execution, and monitoring of projects related to the design, development, production, and distribution of plastic packaging products.

After-sales service

After-sales service in the plastic moulding industry refers to the range of activities and support that a company provides to its customers after they have purchased plastic packaging products or services. The goal of after-sales service is to ensure customer satisfaction, address any issues that may arise, and build long-term relationships with clients. In the context of the plastic moulding industry, after-sales service includes various aspects.